Juyuan Union Technology (Shenzhen) Co., Ltd. offers pre- and post-production DFM & DFA manufacturability checks in its one-stop electronic assembly services. The aim is to comprehensively review design documents before production, identifying potential or potential problems that may arise during PCB manufacturing and assembly. This improves the customer's design, avoiding PCB/material/soldering costs due to design errors and enhancing product manufacturability and assemblability. After production, suggestions for improvement are provided regarding design flaws and other issues, preventing batch losses during subsequent production and assisting customers in the transition from prototyping to mass production.

DFM (Design for Manufacturing) and DFA (Design for Assembly) are key components. By reviewing design documents using DFM/DFA, our engineers can prevent potential manufacturing and assembly problems at the design stage, improving your design before production begins. This reduces costs incurred later due to improper PCB design, incorrect component selection, etc., ultimately improving overall product quality.

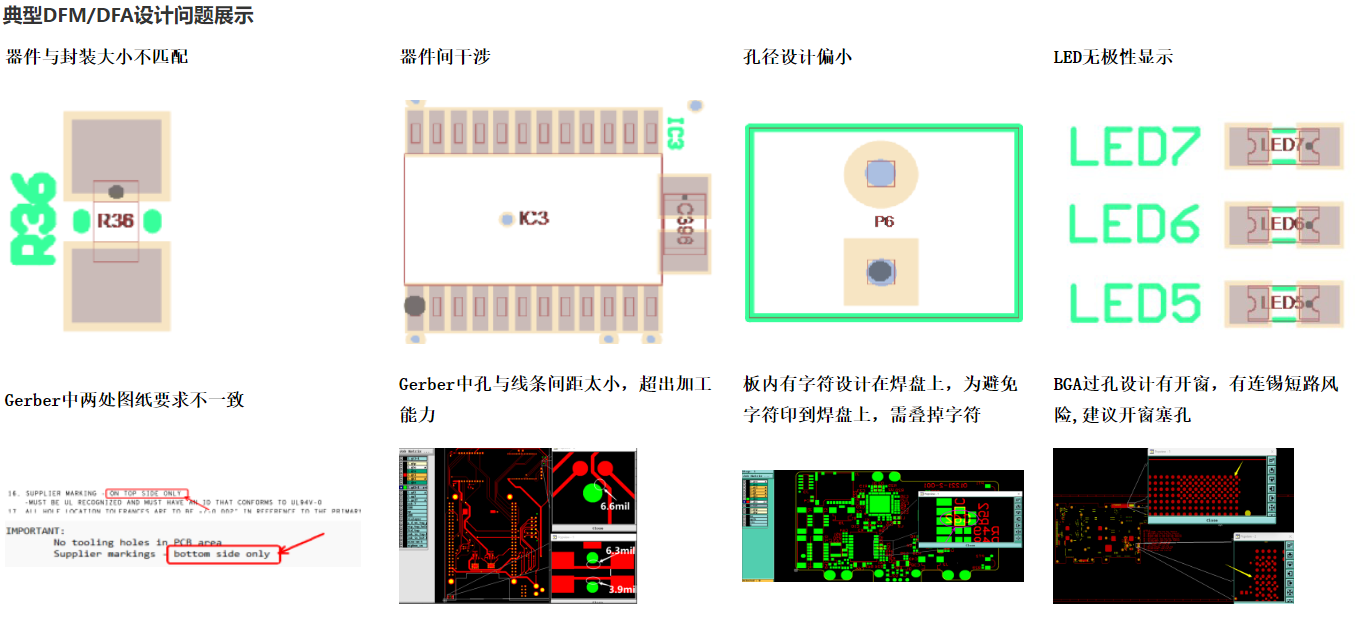

DFM/DFA inspection occurs at the very beginning of product manufacturing and is a unique service offered by our company. Its main inspection content covers all aspects of the PCB and PCBA. DFM focuses on eliminating PCB design factors that hinder manufacturing, while DFA focuses on eliminating potential assembly errors.

Main Contents of DFM/DFA Inspection

1. Are all necessary manufacturing and assembly documents complete, complete, or consistent?

2. Are there any PCB design anomalies?

3. Does the design meet PCB manufacturing process capabilities?

4. BOM and coordinate file inspection and cross-checking

5. Is the component and pad design compatible?

6. Component spacing inspection, component interference check

7. Are there indications for component polarity or orientation?

8. Other items that affect manufacturing and assembly, etc.